Need Technical Support for Your Valve Project?

Research and Development

Valve Research and Development drives innovation in performance, durability, and efficiency. We focus on material breakthroughs, design upgrades, and tech solutions to tackle leaks, corrosion, and high-pressure challenges. Explore our R&D advancements.

Valve Maintenance & Care

Valve maintenance and care are vital for preventing leaks, avoiding breakdowns, and extending service life. Explore expert tips: daily inspections, proper lubrication, seal maintenance, and fixing common issues to keep valves running smoothly.

Valve Technical FAQs

Valve Technical FAQs answer common questions: Why valves leak, how often to maintain them, material compatibility, installation issues, and troubleshooting steps. Get expert insights to solve problems fast—no guesswork. Find answers to your valve technical queries here.

How to maintain globe valves

Globe valves are essential for precise flow control in pipelines, but like all mechanical components, they require proper maintenance to function efficiently. Read more

How to install a gate valve correctly

Gate valves are critical components for controlling fluid flow in industrial pipelines. Proper installation ensures system efficiency, leak prevention, and extended service life, while errors may cause leakage Read more

Why Does the Gate Valve Leak

A leaking gate valve in industrial pipelines isn’t just a minor nuisance—it can disrupt operations, waste resources, increase maintenance costs, and even pose safety risks (e.g., with corrosive or high-pressure media). Understanding the root causes of leaks is key to preventing them Read more

Difference between API 600 and API 6D gate valves

For industrial buyers sourcing gate valves, understanding standards like API 600 and API 6D is critical—choosing the wrong one can lead to system inefficiencies, safety risks, or compliance failures. While both govern high-quality gate valves, their design goals, applications, and specifications differ significantly. Read more

What is the service life of a gate valve

Industrial gate valves are workhorses in pipelines, controlling the flow of liquids, gases, and slurries across sectors like oil & gas, water treatment, and manufacturing. A common question for buyers and operators is: “How long does a gate valve last?” The answer depends on multiple factors—from design quality to operating conditions. Read more

Can gate valves be used for corrosive media

Corrosive media—such as acids, alkalis, saltwater, and industrial chemicals—pose unique challenges for pipeline components. A common question for industrial buyers is: “Can gate valves handle these harsh substances?” The short answer is yes—if properly selected. Read more

Smaller, lighter and requiring less operating force than gate or globe valves, ball valves are available in a variety of designs and materials that provide flexibility, durability and ease-of-use. Ball valves are favored across industries for piping systems involved in: Cooling. Mixing.

It controls fluid flow in pipelines by rotating a ball with a bore; used in plumbing, oil/gas, and industrial systems for quick on/off or throttling.

A ball valve works by rotating a spherical ball (with a central bore) inside the valve body. When the bore aligns with the pipeline, fluid flows; rotating the handle 90 degrees turns the ball, blocking flow with its solid part.

Yes, some ball valves are designed for high temperatures. Their suitability depends on materials—metal-seated valves with heat-resistant alloys (e.g., stainless steel) work in high-temperature systems like industrial boilers.

Common materials for high-temperature ball valves include: stainless steel (316, 304) for bodies/balls; Inconel or Hastelloy for extreme heat; metal seats (e.g., carbon steel, stainless steel); and graphite packing for stem sealing.

The four main types of ball valves are:

Floating Ball Valve: The ball is free to move, suited for small-to-medium pressures.

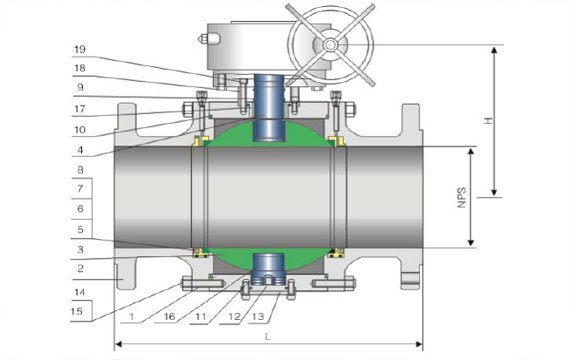

Trunnion Ball Valve: The ball is anchored, ideal for high-pressure systems.

Full Port Ball Valve: The bore matches pipe diameter, minimizing pressure drop.

Reduced Port Ball Valve: The bore is smaller, reducing flow capacity and cost.

Ball valves with integrated drains are designed to simplify maintenance, system shutdown, and fluid evacuation in industrial and civil piping networks. This configuration, which typically features a side drain outlet, allows users to discharge residual fluids from the system without having to disassemble pipes.

A 3-way ball valve is a type of valve used to control the flow of fluids (such as water, gas, or steam) by rotating a ball with a bore inside the valve body. It has three ports and is designed for diversion, mixing, or direction change of flow. There are two main types:

L-type Valve: Connects two orthogonal pipelines while shutting off the third, used for flow direction changes.

T-type Valve: Allows all three pipelines to interconnect or shuts off one, enabling split or merge flow functions

The primary advantage of a ball valve is its exceptional reliability and tight sealing in shut-off applications. The quarter-turn operation allows for quick opening and closing, while the design of the ball and seat ensures a bubble-tight seal, minimizing leakage. This robust construction, often with minimal parts, makes ball valves highly durable, low-maintenance, and suitable for a wide range of pressures and temperatures. They offer low flow resistance in the full-open position and are effective with various media, including water, oil, gas, and corrosive fluids.