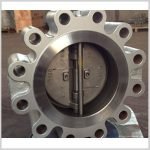

Pressure seal tilting disc check valves

ASME B16.34 Tilting Disc Check Valve – High-Pressure, Low-Flow Efficiency

Key Structural Features

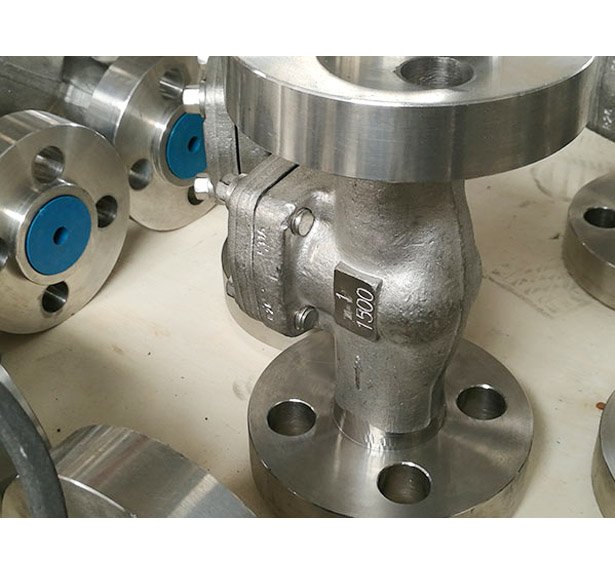

✅ Pressure-Seal Bonnet Design:

ASME B16.34: ASTM A216 WCB body ensures zero leakage under extreme conditions (Class 1500 LB/PN250).

RTJ Flanged Ends (ASME B16.5): Reliable metal-to-metal sealing for high-pressure oil, gas, and steam pipelines (up to 595°C).

✅ Tilting Disc Mechanism:

Pivoted Center Disc: Maintains full-open stability at low flow rates, reducing cracking pressure vs. swing check valves.

Streamlined Flow Path: Low flow resistance and energy loss in low-pressure systems (DN50~DN600).

✅ Silent & Durable Performance:

Impact-Free Closure: Slow disc seating eliminates noise and vibration.

Micro-Elastic Metal Seats: Bubble-tight sealing (API 598 Class VI) with extended service life.

✅ Versatile Configurations:

End Connections: RTJ/RF flanges (ASME B16.5) or butt weld (ASME B16.25).

Material Options: WCB, WC6, CF8M, LCB, etc., for corrosive, cryogenic, or high-temperature media.